With leaks at a minimum and air flow at its maximum, the cost of moving either heated or cooled air is less than when other types of ducts are used. This will improve the quality of the air that you will breathe in your home or commercial building. Tighter joints mean that less dust, pollen and other contaminants are able to infiltrate the system. This means it might come out of the air grate/vent with less force than it should – and that means less heated or cooled air gets into your living space, especially in rooms that are furthest from the air handler. When there is friction – yes, even with air – inside the duct, the PSI drops.

This provides equal and consistent pressure inside the whole system and allows the air to flow evenly and efficiently, which also results in lower energy use. Because of its design, there is less of a pressure drop in systems composed of spiral ducts. The round spiral-wound duct provides an inner surface with almost no air drag or resistance. Spiral duct systems not only have no joints along the length of each section, which isn’t true of sheet metal ductwork, but have a seal at the joints that meets or exceeds the highest industry air-leakage standards. Anywhere from 25-40% of the air in forced air systems is usually lost through leakage in ducts that are in attics or crawl spaces. One of the biggest issues with most HVAC ductwork is getting a good air seal at connections and joints. When compared to either standard rectangular or round ductwork, spiral ductwork has a number of definite pluses. Here are spiral ducts advantages and disadvantages. This approach can be cheaper than framing in space for the ducts and creating openings for air vents. They are hung from the ceiling, in most cases.

#10 spiral duct install#

When there is no room in the ceiling and you don’t want to install ductwork in unheated or uncooled space (outside, in the attic or garage, for example), spiral ducts work well. This is true in commercial settings where an “industrial chic” aesthetic is desired.įunction: Spiral ductwork is attractively made, so that it can be “out in the open” if necessary, as we’ve said. There are two common reasons to use spiral ducts – looks and functionality.Īppearance: In residential settings, spiral ductwork can be attractive when ceiling height is 10 feet or higher and the space has contemporary or urban design. When the architect or builder wants them to “disappear,” they are often painted to match the ceiling and walls and also makes them blend in so that we just don’t notice them.

#10 spiral duct movie#

Warehouses, factories, schools, large churches, movie theaters and athletic venues are a few places where they are often found – but you might have to look for them. Where to Use Spiral DuctworkĪs noted, spiral ducts are most often found in commercial settings. One manufacturer advertises flat oval sizes from 3” x 12” to a whopping 36” diameter x 124” (12-foot) length.

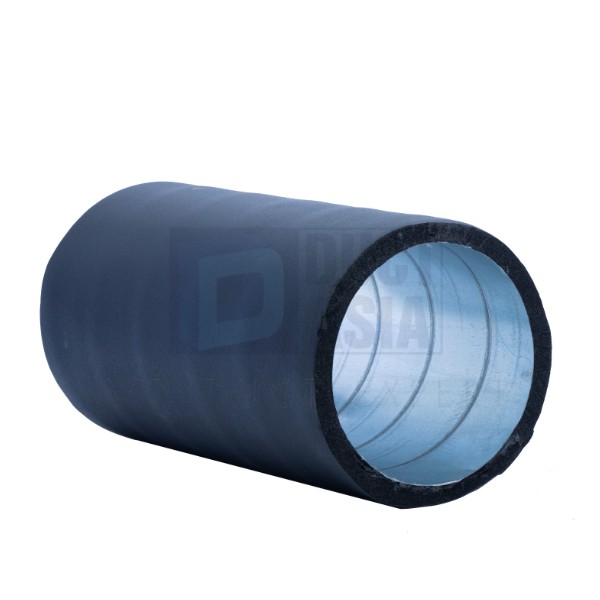

Spiral ducts can be round or flat oval and are commonly produced in sizes from 3” to 63” in diameter. It has its seams on the outside, making the inside surface very smooth and having low resistance to airflow.

Spiral duct is a rigid spirally wound tube usually made of galvanized steel, but can also be stainless steel, aluminum or copper. In 1956 a manufacturer in Switzerland invented a machine to produce spiral ductwork. Spiral Ductwork in Homes – Residential Use.

0 kommentar(er)

0 kommentar(er)